Alternative channels like outlet stores, liquidators, or online marketplaces specializing in clearance items provide additional options. Some companies successfully bundle obsolete items with what to do with obsolete inventory popular products to increase perceived value. For seasonal items, strategic storage until the next relevant season may be viable. When selling isn’t feasible, donating inventory can provide tax benefits while supporting charitable causes and enhancing corporate social responsibility profiles. The most effective inventory systems integrate obsolete inventory management alerts directly into daily operational workflows.

- The goal is to improve how you’re managing obsolete inventory with fewer manual checks and faster insights.

- What do you do with assets that no longer serve a function, but are tying up cash and shelf space in your facility?

- Use your inventory management system to analyze sales data by customer or customer group, and act on these insights to improve your obsolete inventory management.

- Managing obsolete inventory requires a structured approach to maximize recovery value.

- It allows the clearance of non-moving stock from your records, thus keeping the balance sheet representative of current assets.

- According to Deskera, there’s an estimated $100 billion in dead stock in the retail industry at any moment.

Considering Sunk Costs and Future Value

Crafting precise predictions requires deep insight into your target audience as well as external factors like economic shifts or seasonal changes. Leveraging advanced analytics can vastly improve forecasting accuracy, thereby reducing the risks of excess inventory buildup. Having obsolete inventory may silently erode your brand’s image in the competitive market.

Business Assets: Types, Examples, and Management Strategies

Investing in advanced inventory management software can significantly enhance a company’s ability to prevent obsolete inventory. By implementing these proactive strategies, businesses can effectively minimize the risk of accumulating obsolete inventory, ensuring that their stock levels align with actual demand and market conditions. Reducing obsolete inventory requires a multifaceted approach that integrates proactive planning, dynamic sales strategies, and continuous improvement. One effective strategy is to implement just-in-time (JIT) inventory management. By aligning inventory levels closely with production schedules and customer demand, businesses can minimize excess stock and reduce the risk of obsolescence. This approach necessitates a robust supply chain and reliable suppliers to ensure timely deliveries, but the benefits in terms of reduced storage costs and improved cash flow can be substantial.

Monitoring Inventory Levels in Real Time

- By leveraging historical data, market trends, and sales input, businesses can develop robust forecasting models that anticipate future demand and inform inventory planning decisions.

- Analyzing historical sales data can reveal trends and patterns in customer demand.

- Unsellable stock ties up capital that could otherwise be used for more productive purposes, such as investing in new product lines or expanding market reach.

- Consumer trends and seasonal shifts play a significant role in the fashion and retail sectors.

- Harness the power of inventory management software to streamline your operations.

- Products that fail to meet consumer expectations quickly become undesirable, adding to the pile of obsolete inventory.

Almost every business has obsolete inventory, which ties up capital, increases storage costs, and drains resources. Obsolete or dead stock is the outdated and unsellable excess stock that occupies space in your warehouse. It may have entered the realms of obsolescence due to changes in demand, technological upgrades, or poor forecasting. Efficiently managing storage and handling costs is critical, but the impact of obsolete inventory on productivity cannot be overlooked. High rates of unsellable stock lead to wasted resources as employees spend time sorting, organising, and accounting for dead inventory that contributes no value to operations or sales. Accounting for obsolete inventory involves recognizing its decreased value in financial statements.

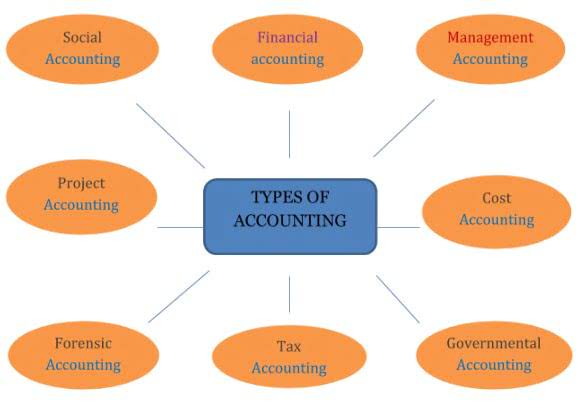

Key Concepts in Obsolete Inventory Accounting

By leveraging historical sales data and market trends, these systems allow businesses to predict future demand more precisely, helping to avoid the pitfalls of misaligned procurements. They http://mipagina.online/2022/03/30/premium-discount-amortization-methodology/ should also prioritize just-in-time inventory management and maintain optimal inventory levels to minimize excess inventory. By taking a proactive approach to inventory management, businesses can reduce the risk of incurring unnecessary storage and handling costs related to obsolete inventory.

Managing and minimizing obsolete inventory is important to ensure the efficiency and profitability of a business. GAAP requires that obsolete inventory be accounted for as soon as it’s identified. This typically involves either writing down the inventory to its net realizable value or writing it off entirely if it has no value. These adjustments must be reflected in the financial statements promptly to ensure accurate reporting and tax deductions. Finally, consider donating excess stock to real estate cash flow charitable organizations or community outreach programs.